Next-Generation Plastic Injection Tooling for Precision Bottle Caps

2026-02-09 17:06

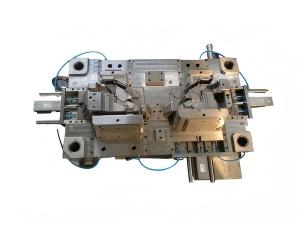

PROSPERITY TECHNOLOGY DEVELOPMENT CO.,LTD today introduced its latest Plastic Injection Tooling for Bottle Cap manufacturing, optimized with advanced insert molding, precise mold layout, robust over mould integration, versatile Two-shots Injection Mould sequencing, and high-throughput stack mould design. This turnkey solution delivers German standard thread accuracy (PG), 0.5 mm tolerance, and 4-cavity output in durable PP material.

With insert molding at its core, this tooling embeds metal inserts seamlessly into the cap body, enhancing structural strength for automotive interior parts and reducing secondary operations. The optimized mold layout balances cooling channels and ejector pins to guarantee uniform wall thickness and consistent fills across all cavities. Over mould capabilities allow multi-material bonding—such as sealing gaskets or decorative inserts—directly in a single cycle, eliminating manual assembly steps.

The Two-shots Injection Mould process enables sequential injection of two materials or colors in one tool. By combining a YUDO 2-point hot nozzle hot runner system with an LKM mould base and 1.2344 cavity & core steel, cycle times improve by up to 25%. This precision sequencing achieves crisp feature definition on complex geometries and sustains tight tolerances under HASCO STANDARD certification.

To maximize productivity, the stack mould configuration doubles effective cavities without expanding the machine footprint. The stack mould design routes molten PP through dual-level manifolds, delivering consistent pressure and temperature across eight contact points. This high-density approach increases throughput up to 100,000 caps per week while reducing energy consumption by 20%.

Quality assurance protocols include dimensional inspection of thread pitch, bore integrity, and surface finish. Insert molding trials verify metal-to-PP adhesion, mold layout simulations confirm thermal uniformity, and over mould tests assess bond strength. Two-shots Injection Mould evaluations ensure phase-change stability, while stack mould trials validate balanced fill and venting.

Engineers benefit from comprehensive support: on-site training in insert molding best practices, mold layout optimization, over mould parameter tuning, Two-shots Injection Mould sequencing, and stack mould calibration. Modular tooling components and retrofit kits enable rapid mold repairs and upgrades.

Conclusion:

PROSPERITY TECHNOLOGY DEVELOPMENT CO.,LTD’s Bottle Cap Plastic Injection Tooling sets a new industry benchmark. By integrating insert molding, precision mold layout, seamless over mould integration, advanced Two-shots Injection Mould techniques, and scalable stack mould architecture, this solution delivers unparalleled quality, efficiency, and flexibility. For turnkey injection tooling that meets the strictest standards, contact us today.

Contact us

Email: spark@prosperitymould.com

Phone: +86-755-23638965

Website: www.prosperitymould.com