News

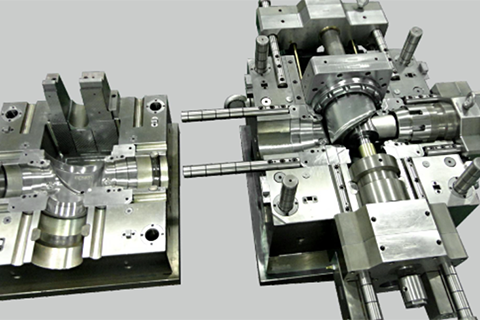

Successful construction of PA+GF45% material truck pump body structural parts mould.

In 2023, our company created its own official foreign trade website

At the same time of busy production, our company regularly organizes employees to participate in company team building activities to enhance cohesion and build a harmonious, upward and united team.

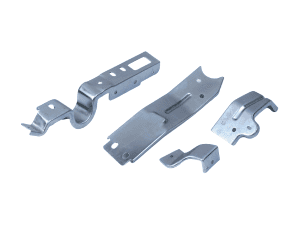

We specialize in precision sheet-metal fabrication for automotive chassis components and engine-support brackets. Leveraging in-house tooling and advanced die technologies, we deliver punching, bending, blanking, and cutting services to exact customer specifications.

High-precision mold processing and production for communication product components—covering air conditioners, fax machines, portable devices, intercom systems and SATCOM equipment.

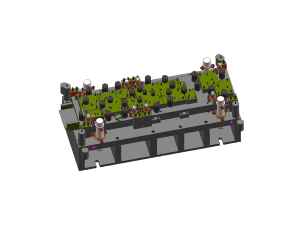

punch die insert diebutton shape punch=die insert stock locater block ...

Magna Steyr turck parts/Exhaust pipe fixing support accessories Progressive die/Bend MTL:STEEL VSHR 170A STD 311-0003 T 3.0MM Rivert second process CAE 3d Stamping die design

Transparent thin-wall medical products are produced in professional dust-free purification workshops.

Part name:Electric iron and electrical switch Material:SMC/BMC Mould type: Thermoset Mold Cavity&Core: H13 Mould base: LKM Cold runner: Edge gate Tolerance: +/-0.2mm

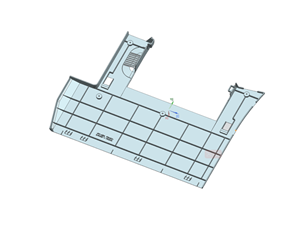

Part name: Network host controller panel Material: ABS+PC Mould type: 1Cavity number Cavity&Core: 1.2718H Mould base: LKM Cold runner: Point gate Tolerance 0.5mm Nitrogen assisted injection molding