- Home

- >

- News

- >

- Industry News

- >

News

In the realm of modern manufacturing, die casting stands as a cornerstone process, enabling the mass production of complex, high-strength, and lightweight metal parts. Among the various materials utilized, aluminum alloy die-casting, Zinc alloy die casting, and magnesium alloy die-casting each offer unique properties that cater to diverse and demanding applications. These processes are pivotal in creating components that meet rigorous standards for durability, precision, and efficiency.

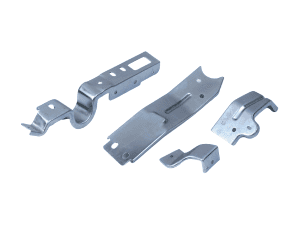

We specialize in precision sheet-metal fabrication for automotive chassis components and engine-support brackets. Leveraging in-house tooling and advanced die technologies, we deliver punching, bending, blanking, and cutting services to exact customer specifications.

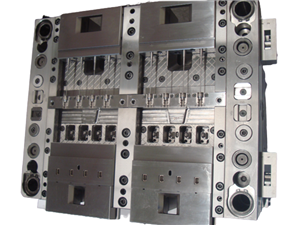

High-precision mold processing and production for communication product components—covering air conditioners, fax machines, portable devices, intercom systems and SATCOM equipment.

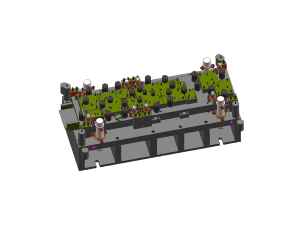

punch die insert diebutton shape punch=die insert stock locater block ...

Magna Steyr turck parts/Exhaust pipe fixing support accessories Progressive die/Bend MTL:STEEL VSHR 170A STD 311-0003 T 3.0MM Rivert second process CAE 3d Stamping die design

Transparent thin-wall medical products are produced in professional dust-free purification workshops.

Part name:Electric iron and electrical switch Material:SMC/BMC Mould type: Thermoset Mold Cavity&Core: H13 Mould base: LKM Cold runner: Edge gate Tolerance: +/-0.2mm

Part name: Network host controller panel Material: ABS+PC Mould type: 1Cavity number Cavity&Core: 1.2718H Mould base: LKM Cold runner: Point gate Tolerance 0.5mm Nitrogen assisted injection molding

Progressive die+Hand transfer die 3D/2D drawings Layout design drawing DFM/analysis report Stamping die design Feeder specifications Processing analysis by numerical simulation(NS) of deep drawing step in progressive die(DDSPD) quickly and accurately was very important. Material:STEEL V-1140 ALT ASTM A366/A620 STD 111,401 T3~8 +0.2/-0.2MM

Precision Medical Infusion Needle Manufacturing Specifications Component Overview Part Name: Medical Infusion Needle (Class II Medical Device) Primary Material: PP 9074MED (USP Class VI Certified) Wall Thickness: 0.7mm ±0.03mm (Critical Flow Path Sections) Surface Finish: SPI-A2 (Ra ≤ 0.025μm for Fluid Contact Surfaces)

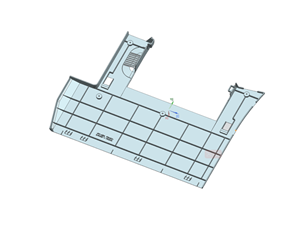

High-Precision Injection Molding for Electric Vehicle Battery Storage Components Part Name: Electric Vehicle Battery Storage Material: PA66 (BASELL) – High-temperature, flame-retardant nylon for superior mechanical and thermal stability Mold Type: Insert Molding / Injection Molding (Multi-Cavity Production) Cavity & Core: H13 Tool Steel (Hardened to 48-52 HRC for extended mold life) Mold Base: LKM Standard (DME-compatible for global serviceability) Hot Runner System: Moldmaster 4-Point Hot Nozzle (Precision temperature control for consistent fill) Tolerance: ±0.2mm (Critical for battery sealing surfaces)

Sports Equipment Zine Alloy Die Casting Die casting is a manufacturing process in which molten metal is injected into a steel mold, known as a die, under high pressure. The molten metal fills the mold cavity and solidifies, taking the shape of the mold. This process allows for the production of complex shapes with high precision and consistency Zine Alloy Die Casting mold