Innovations in Stamping Die Structural Design

2025-08-04 10:24Innovations in Stamping Die Structural Design Drive Efficiency in Automotive Component Manufacturing

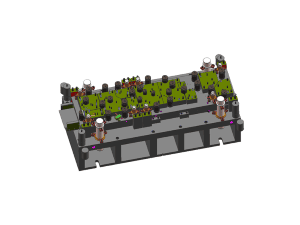

As automotive suppliers face increasing pressure to deliver complex parts faster, advanced stamping die structural design methodologies are transforming production. Magna Steyr's latest truck exhaust pipe support accessories demonstrate this shift, utilizing progressive die technology with 3D mould design precision for high-volume output.

Cutting-Edge Engineering Approaches

The VSHR 170A steel components (3.0mm thickness) showcase three critical advancements:

Integrated CAE/CAM Workflows

Virtual forming simulations reduce physical trials by 40%

CAM programming optimizes tool paths for rivet second process operations

Springback compensation algorithms improve bend accuracy

DFMA-Optimized Strip Layout Design

Material utilization rates exceeding 85%

Multi-stage progression planning for:

Piercing

Forming

Trimming

Final bending

3D Stamping Die Design

Parametric modeling enables rapid design iterations

Interference checking prevents costly rework

Motion simulation validates die mechanics

Technical Specifications

| Parameter | Value |

|---|---|

| Material | STEEL VSHR 170A STD 311-0003 |

| Thickness | 3.0mm ±0.1mm |

| Tolerance | ±0.05mm (critical features) |

| Production Rate | 25-30 strokes/minute |

One-Stop Service Capabilities

Leading manufacturers now provide complete solutions:

Product Design Analysis (DFM/DFA)

Die Structure Engineering (including strip layout design)

Tooling Fabrication

Production Validation

Industry Impact

These advancements address key challenges:

15% shorter lead times for progressive die projects

30% cost reduction through DFMA principles

Improved part consistency for safety-critical exhaust pipe fixing supports

Future Outlook:

With CAE/CAM integration becoming standard, next-generation stamping die structural design will increasingly leverage:

AI-driven process optimization

Digital twin technology

Additive manufacturing for conformal cooling channels