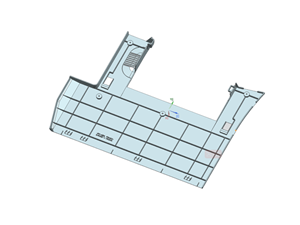

Nitrogen Injection Tooling

2025-06-26 10:56Network Host Controller Panel: Advanced Manufacturing with Nitrogen Assisted Injection Tooling

Part Specifications:

Part Name: Network Host Controller Panel

Material: ABS+PC (High-strength thermoplastic blend)

Mold Configuration:

Mold Type: 1-Cavity

Core & Cavity Steel: 1.2718H (Premium hot-work tool steel for high wear resistance)

Mold Base: LKM Standard (DME-compatible)

Gating System: Cold runner with precision point gate

Tolerance: ±0.5mm (Critical for flatness requirements)

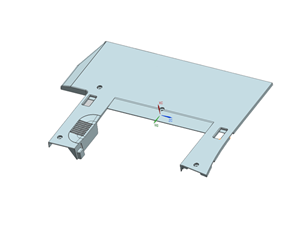

Key Manufacturing Process:

This component utilizes Nitrogen Assisted Injection Tooling to achieve:

✔ Ultra-thin wall consistency (0.8-1.2mm typical)

✔ Absolute flatness ≤0.3mm/m²

✔ Zero visible shrinkage marks

Technical Highlights:

1. Nitrogen Assisted Injection Tooling Implementation

Gas Pressure: 150-300 bar nitrogen injection

Timing Sequence: Precisely synchronized with plastic injection phase

Benefits vs Conventional Molding:

40% reduction in cooling time

Eliminates sink marks on large flat surfaces

Improves dimensional stability for tight-tolerance parts

2. Multi-Process Compatibility

Insert Molding:

Metal EMI shields or connectors can be embedded

Pre-insert temperature control to prevent thermal stress

Overmolding:

Secondary soft-touch TPE layers possible

Bonding strength >8N/mm²

PVC Injection Molding Alternative:

For flame-retardant versions (UL94 V-0 compliant)

Requires specialized corrosion-resistant mold coatings

Quality Assurance Features:

▸ Mold flow analysis prior to tool fabrication

▸ In-mold sensors for pressure/temperature monitoring

▸ Post-molding CMM verification of flatness

▸ 100% visual inspection for surface defects

Production Considerations:

Cycle Time: 28-35 seconds (varies with wall thickness)

Annual Capacity: ~250,000 pieces with single-cavity tool

Tool Maintenance:

Monthly nitrogen valve inspection

Biannual mold surface refurbishment

Industry Applications:

◉ 5G network equipment enclosures

◉ Industrial IoT control panels

◉ Automotive infotainment systems

◉ Medical device housings

This manufacturing approach combines plastic injection efficiency with Nitrogen Assisted Injection Tooling precision to produce high-specification technical components. The process is equally effective for insert molding of hybrid structures or overmolding for enhanced ergonomics. For cost-sensitive applications, PVC injection molding variants can be developed using compatible material formulations.