Precision Plastic Mould Solutions

2025-06-13 15:23Precision Medical Infusion Needle Manufacturing Specifications

Component Overview

Part Name: Medical Infusion Needle (Class II Medical Device)

Primary Material: PP 9074MED (USP Class VI Certified)

Wall Thickness: 0.7mm ±0.03mm (Critical Flow Path Sections)

Surface Finish: SPI-A2 (Ra ≤ 0.025μm for Fluid Contact Surfaces)

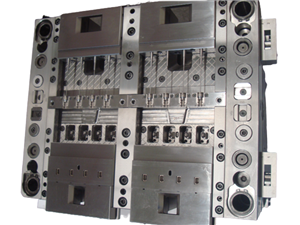

Advanced Tooling Configuration

Mold System: 16-Cavity High-Precision Stack Mold

Core/Cavity Material: Uddeholm M300 Tool Steel

Hardened to 52-54 HRC

Mirror Polished with EDM Texturing

PVD Coated for Corrosion Resistance

Mold Base: NAK80 Pre-Hardened Steel (40-42 HRC)

Integrated Temperature Control Channels

Guided Ejector System with Sleeved Leaders

Hot Runner Technology

System: Moldmaster 8-Point Hot Nozzle System

Individual Zone Temperature Control (±0.5°C)

Balanced Melt Flow Distribution

Quick-Change Nozzle Tips for Different Gate Styles

Gate Type: 0.35mm Hemispherical Hot Tip Gate

Automatic Gate Cutting System

Zero Drool Shut-Off Mechanism

Injection Molding Process

Machine: Toshiba EC-SX 180 All-Electric Press

Clamping Force: 1800 kN

Injection Accuracy: ±0.15% Shot Weight

Repeatability: ±0.002mm Positioning

Process Parameters:

Melt Temp: 220-230°C (Precision Controlled)

Mold Temp: 60-65°C (Water-Oil Hybrid System)

Injection Speed: 120mm/s (3-Stage Profile)

Packing Pressure: 80MPa (Decay Curve Controlled)

Quality Assurance Protocols

Dimensional Verification:

Optical Comparator Inspection (0.001mm Resolution)

CMM Sampling Every 4 Hours (Full GD&T Report)

Functional Testing:

Flow Rate Testing at 23°C ±1°C

Burst Pressure Verification (Minimum 300kPa)

Material Compliance:

FTIR Material Conformity Testing

USP <88> Biological Reactivity Testing

Production Validation

Process Capability: CpK ≥ 1.67 (Critical Dimensions)

Annual Capacity: 18 Million Units (3-Shift Operation)

Cleanroom Standards: ISO Class 7 Molding Environment

Validation Documentation: Full IQ/OQ/PQ Package Available

Regulatory Support

FDA 21 CFR Part 820 Compliance

ISO 13485:2016 Certified Process

REACH & RoHS Material Certification