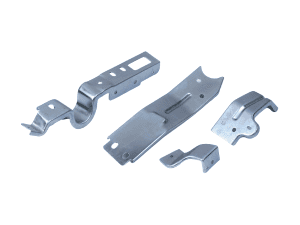

Produce Sheet Metal Parts

2025-10-10 15:26

We specialize in precision sheet-metal fabrication for automotive chassis components and engine-support brackets. Leveraging in-house tooling and advanced die technologies, we deliver punching, bending, blanking, and cutting services to exact customer specifications.

Core Processes

• Progressive Die Stamping

– Multi-stage die that performs punching, bending, and trimming in one automated pass for high-volume runs.

• Single-Operation Die (Transfer Die)

– Dedicated tool for individual steps (punching, bending, or blanking), ideal for low- to medium-volume production and quick die changes.

• Forming (Bending) Die

– Precision V- and U-bending tools for accurate flange angles and consistent spring-back control.

• Blanking Die

– High-tolerance shearing of flat blanks, minimizing burrs and maintaining exact part dimensions.

Materials & Standards

• Material: Mild steel, high-strength low-alloy (HSLA), stainless steel, aluminum alloys

• Thickness Range: 0.5 – 6.0 mm (custom on request)

• Standard: MTL SEHD (Sheet-Metal Die Standard)

• Tolerances: ±0.05 mm on stamped features; ±0.1 mm on formed dimensions

Key Features & Benefits

• Integrated Punching-Bending-Blanking

– Consolidated operations reduce handling, cycle time, and part cost.

• High Throughput & Repeatability

– Progressive dies achieve cycle rates up to 30 strokes/min with consistent part quality.

• Precision Bend Control

– CNC-controlled press brakes and form dies ensure exact bend angles and minimal spring-back.

• Sharp, Burr-Free Edges

– Fine-tuned blanking dies deliver clean cut edges and improve downstream weld or assembly.

• Durable Tooling

– Hardened die steels and surface treatments extend die life beyond 500,000 strokes.

Typical Applications

• Automotive Chassis Brackets & Reinforcements

• Engine Support Card & Mounting Parts

• Structural Panels and Chassis Rails

• Electrical Enclosures and Chassis Frames

• Appliance and Industrial Equipment Housings

Quality Assurance

• First-Article Inspection with CMM report

• In-process die monitoring and maintenance

• Final dimension and surface-finish checks

• ISO 9001–compliant production environment

Why Partner With Us?

• One-Stop Die & Stamping Service—from tool design to finished parts

• Rapid Tooling Lead Times—standard single dies in 4–6 weeks;

• Flexible Volume Capability—prototype batches to annual volumes of 1,000,000+ parts

• Expert Technical Support—DFM reviews, material recommendations, and process optimization

Contact Information

Ready to prototype or ramp up production of your sheet-metal chassis parts?

Email: spark@prosperitymould.com

Phone: +86-755-23638965

Website: www.prosperitymould.com

Delivering precision-stamped, bent, and blanked components with superior tooling and responsive service.